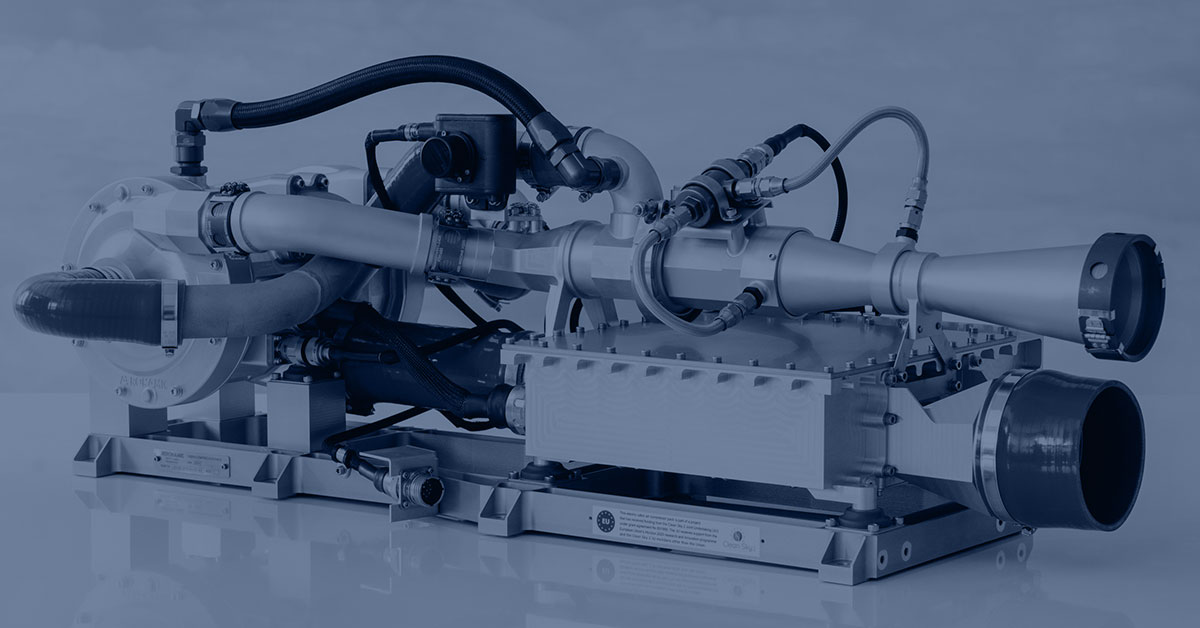

Scroll Compressor

Our scroll compressor is an essential component of a galley cooling system. It’s powered by an electric motor, which meets demands for the more electric aircraft. In all Airbus A350 aircraft, this scroll compressor’s job is to cool the avionics, galleys, and in-flight entertainment systems. Aeronamic is this component’s single source supplier.

We assemble and test scroll compressors in the Netherlands. Parts manufacturing and special processes, such as anodizing and phosphating, take place in our facilities in both the Netherlands and Romania. Besides producing the compressor, we are also responsible for the system’s MRO throughout the aircraft program’s lifetime.